Durans and Klinger glasses

Klinger Glass

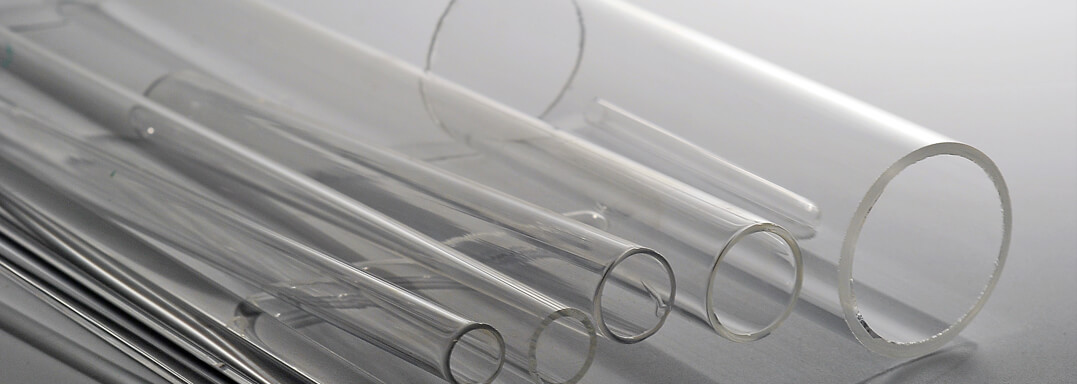

“Durance” glass is a smooth glass, made from thermally hardened borosilicate glass. Both of its surfaces – viewing and opposite – are smooth. is a smooth glass, made from thermally hardened borosilicate glass. Both of its surfaces – the viewing and the opposite – are smooth.

The Durans watermarking glass is used in the following boiler equipment to indicate the level of the petrochemical liquid:

- In steam boilers that do not have a mica gasket, with a pressure of 3.5 MPa (35 kgf / sq. Cm) and a temperature not exceeding 243С.

- In steam boilers that do not have a mica gasket, with a pressure of 3.5 MPa (35 kgf / sq. Cm) and a temperature not exceeding 243С.

- In steam boilers with pressure of 3.5 to 12 MPa (over 35 to 120 kgf / sq. Cm) inclusive, it is possible to use the mica gasket (GOST 13752), which will protect the glass from direct exposure to steam and water.

“Duran’s” glass in accordance with GOST (Russia) is a colorless glass with polished parallel surfaces. in accordance with GOST is a colorless glass with polished parallel surfaces. Provided that this does not reduce the coefficient of directional light transmission, the greenish, bluish or yellowish shade of the glass is permissible. The number of the directional light transmittance of smooth glasses less than 0.85 per 1 cm is not permissible. For the curvature of the viewing surface with respect to the opposite, the permissible value is 0.2 mm (the length of the glass is less than 190 mm), and 0.3 mm if the length of the glass exceeds 190 mm. The surface of the Durant glass, which is perpendicular to the viewer, may have a curvature not exceeding 2 mm. The limiting deviations are: L – 1.5 mm, W – 1.0 mm, T – + -1.0 mm.

| Number | L, mm | B, mm | S, mm | Mass, kg |

| 1 | 140 | 28 | 17 | 0,152 |

| 2 | 160 | 28 | 17 | 0,184 |

| 3 | 220 | 28 | 17 | 0,26 |

| 4 | 280 | 28 | 17 | 0,336 |

| 5 | 340 | 28 | 17 | 0,41 |

| 6 | 140 | 34 | 17 | 0,172 |

| 7 | 160 | 34 | 17 | 0,204 |

| 8 | 220 | 34 | 17 | 0,28 |

| 9 | 250 | 34 | 17 | 0,317 |

| 10 | 280 | 34 | 17 | 0,356 |

| 11 | 340 | 34 | 17 | 0,43 |

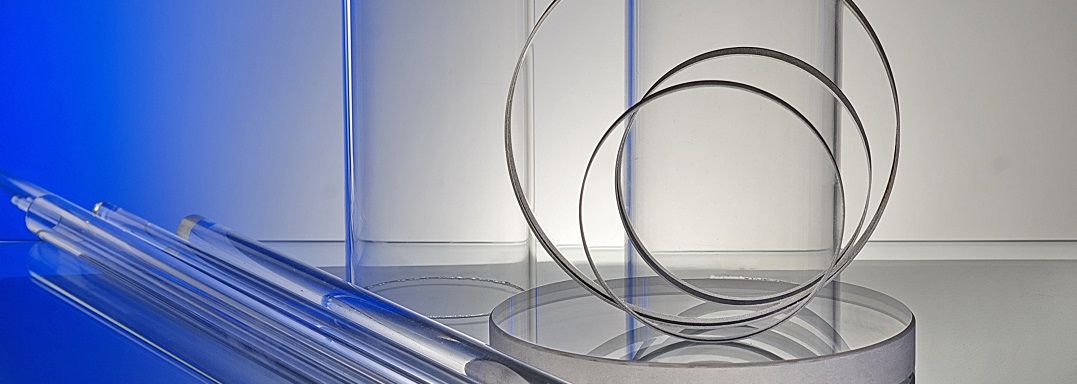

“Klingers” glass

“Klinger” glass is designed to measure the liquid level. It is made from high quality tempered glass and passes additional heat treatment. You can buy Klinger glass right now by placing an order on the website of our company. Detailed consultation of our experienced managers will help you to get all the necessary information about the selected products.

Fields of application of Klinger glasses:

“Klinger” glass is intended for use in boiler equipment. The areas of its application include chemical and pharmaceutical industries, oil refining, food, etc. It is optimal to use the Klinger glass at a places that are vapor saturated and with pressure that not exceeding 35 bar. The features of this reflexive sight glass make it possible to read the readings clearly. In other environments it is rational to use Klinger glass in containers with, pressure of not more than 400 bar and also temperature level not exceeding 400 degrees celsium.

| Number | L, mm | B, mm | S, mm | Mass, kg |

| 0 | 95 | 34 | 17 | 0,11 |

| 1 | 115 | 34 | 17 | 0,132 |

| 2 | 140 | 34 | 17 | 0,162 |

| 3 | 160 | 34 | 17 | 0,195 |

| 4 | 190 | 34 | 17 | 0,288 |

| 5 | 220 | 34 | 17 | 0,264 |

| 6 | 250 | 34 | 17 | 0,301 |

| 7 | 280 | 34 | 17 | 0,338 |

| 8 | 320 | 34 | 17 | 0,387 |

| 9 | 340 | 34 | 17 | 0,41 |

Admissible deviations in accordance with GOST are: L – 1,5 mm, W – 1,0 mm, T ± 1,0.

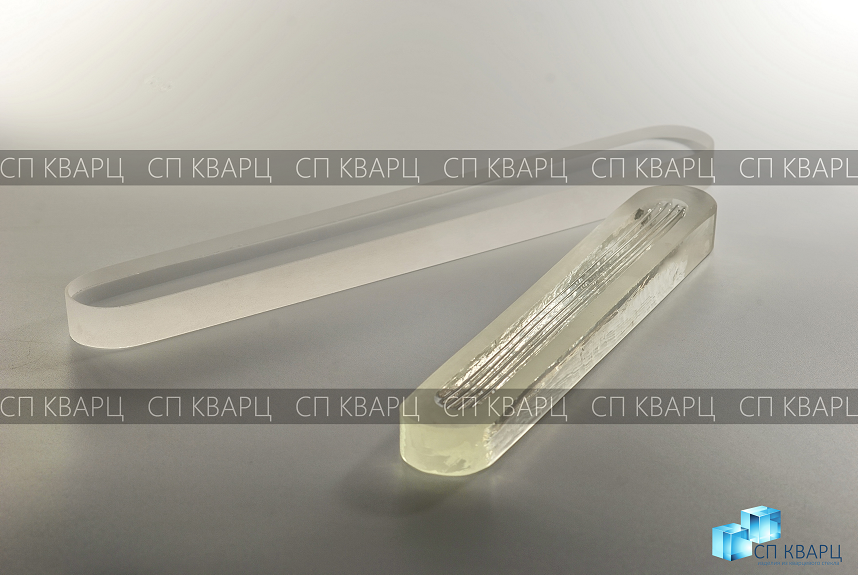

Reflective “Klinger” glass is a glass with a degree of hardening 865 ± 55 nm / cm, which makes it thermally stable. It is able to withstand temperature changes up to 220 degrees. This glass has a polished viewing surface and polished the opposite and is colorless. Glass can have a bluish, yellowish or greenish hue, if this does not reduce the coefficient of directional light transmission. With a length of less than 190 mm, the curvature of the front and the opposite surface cannot exceed 0.2 mm, and with a glass length of more than 190 mm – 0.3 mm. The side surface of the glass should not have a curvature of more than 2 mm.is a glass with a degree of hardening 865 ± 55 nm / cm, which makes it thermally stable. It is able to withstand temperature changes up to 220 degrees. This glass has a polished viewing surface and polished the opposite and is colorless. Glass can have a bluish, yellowish or greenish hue, if this does not reduce the coefficient of directional light transmission. With a length of less than 190 mm, the curvature of the front and the opposite surface cannot exceed 0.2 mm, and with a glass length of more than 190 mm – 0.3 mm. The side surface of the glass should not have a curvature of more than 2 mm.

Chemical composition of glass:

| SiO2 | Аl2O3 | B2O3 | Na2O | K2O | Cl | MeO | Fe2O3 | SO3 | Сверх 100% |

| 73,7+ 0,3 | 3,0+ 0,2 | 17,3+ 0,2 | 4,1+ 0,2 | 1,1+ 0,2 | до 0,15 | до 0,46 | до 0,04 | до 0,15 | NaCl 2,0+ 0,2 Zn – 0,05 |

Examples of the symbol:

Glass corrugated TZ-250-3.5 MPa GOST 1663-81 or Glass corrugated TZ-250-3.5 MPa TU 21-0293167-32-92

Thermally hardened “Klinger” corrugated glass with a length of 250 mm for operation at pressures up to 3.5 MPa (35 kgf / cm2).

send an application